Choosing the Best Materials for Screen Printing

- rashid kadara

- Nov 12

- 4 min read

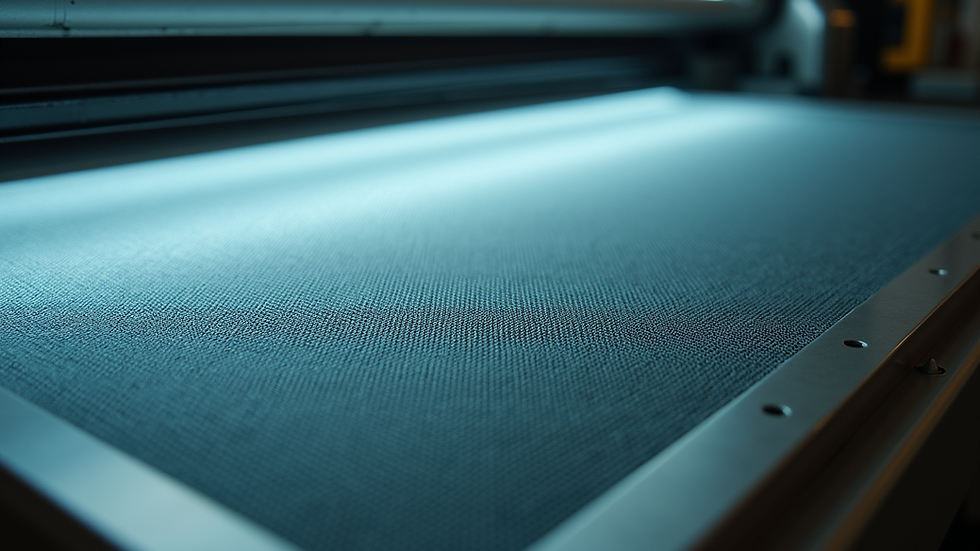

Screen printing is a popular and versatile method for creating vibrant designs on various surfaces. Whether you are printing on fabric, paper, or other materials, selecting the right supplies is crucial to achieving high-quality results. This guide will walk you through the essential screen printing supplies you need and how to choose the best materials for your projects.

Understanding Essential Screen Printing Supplies

Before diving into the specifics of materials, it’s important to understand the core supplies involved in screen printing. These include:

Screens: Frames with mesh stretched over them, which hold the stencil for your design.

Squeegees: Tools used to push ink through the mesh onto the printing surface.

Inks: Various types depending on the material you are printing on.

Emulsions and Chemicals: Used to create the stencil on the screen.

Substrates: The items you are printing on, such as t-shirts, posters, or bags.

Each of these components plays a vital role in the printing process. Choosing the right combination will affect the durability, vibrancy, and overall quality of your prints.

Selecting the Best Screens and Mesh Counts

The screen is the foundation of your print. Screens come in different sizes and mesh counts, which refer to the number of threads per inch in the mesh. The mesh count determines the level of detail and the amount of ink that passes through.

Low mesh counts (60-110): Best for printing bold designs with thick ink layers, such as on textiles.

Medium mesh counts (156-230): Ideal for general-purpose printing with moderate detail.

High mesh counts (305-355 and above): Used for fine details and halftones, often on paper or specialty materials.

When choosing screens, consider the type of ink and substrate. For example, water-based inks require a different mesh count than plastisol inks to achieve the best results.

Choosing the Right Inks for Your Project

Inks are a critical part of screen printing. The type of ink you select depends on the substrate and the desired finish.

Plastisol Ink: Popular for textile printing due to its durability and vibrant colors. It sits on top of the fabric, creating a slightly raised texture.

Water-Based Ink: Penetrates the fabric for a softer feel. It’s eco-friendly and ideal for light-colored garments.

Discharge Ink: Removes dye from the fabric and replaces it with ink color, resulting in a soft print on dark garments.

Specialty Inks: Include metallic, puff, glow-in-the-dark, and UV-reactive inks for creative effects.

Always test inks on your chosen substrate to ensure compatibility and desired results.

Essential Screen Printing Supplies for Stencil Creation

Creating a precise stencil is key to a successful print. This involves using emulsions and chemicals that coat the screen and harden when exposed to light.

Photo Emulsion: A light-sensitive liquid that forms the stencil. It’s applied evenly on the screen and exposed to UV light with your design.

Emulsion Remover: Used to clean screens after printing, allowing you to reuse them.

Degreaser: Prepares the screen by removing oils and residues to ensure proper emulsion adhesion.

Proper handling and storage of these chemicals are important for safety and longevity.

Choosing the Right Substrate for Your Prints

The substrate is the surface you print on, and it greatly influences the choice of materials and techniques.

Textiles: Cotton, polyester, blends, and specialty fabrics each react differently to inks.

Paper and Cardboard: Require inks that dry quickly and adhere well without smudging.

Plastics and Metals: Need inks with strong adhesion and sometimes additional curing processes.

Understanding the substrate’s properties helps you select the best screen printing materials and achieve durable, vibrant prints.

Tips for Maintaining Your Screen Printing Supplies

Proper maintenance extends the life of your equipment and ensures consistent print quality.

Clean screens immediately after use to prevent ink from drying.

Store inks in airtight containers away from direct sunlight.

Regularly check and replace worn squeegees for clean, sharp prints.

Keep emulsions and chemicals sealed and stored in a cool, dark place.

By following these practices, you can avoid common issues like clogged screens and faded prints.

Where to Find Quality Screen Printing Materials

Finding reliable sources for your screen printing materials is essential. For high-quality and affordable options, consider suppliers that specialize in professional-grade products. One excellent resource for screen printing materials offers a wide range of supplies tailored to different needs and budgets.

Investing in quality materials upfront saves time and money in the long run by reducing errors and improving print outcomes.

Final Thoughts on Choosing Screen Printing Supplies

Selecting the best materials for screen printing involves understanding your project’s needs and the characteristics of each supply. From screens and inks to emulsions and substrates, every component affects the final product. By choosing wisely and maintaining your supplies, you can create stunning prints that last.

Whether you are a beginner or an experienced printer, having the right essential screen printing supplies is the foundation of your success. Explore different materials, experiment with techniques, and enjoy the creative process of screen printing.

Comments